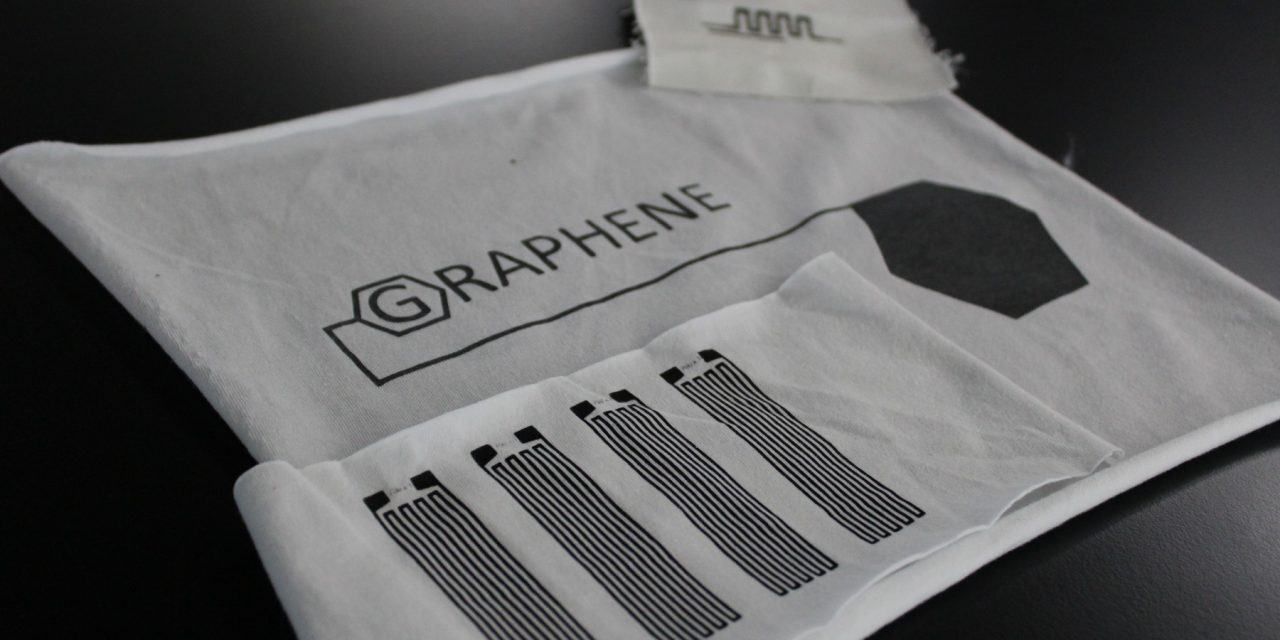

Credit: University of Manchester

Wearable devices and clothing for health monitoring, fitness, military applications and many other things are a huge high technology trend these days. To be wearable as clothing it must fit comfortably without being heavy, stiff or in anyway bulky, without compromising their usefulness, which is the huge barrier for wearables designers today. Enter graphene, which is a super thin lattice of carbon atoms, with many contrasting properties that make it the darling material of scientists. It’s visible to the naked eye and makes a perfect barrier for membranes, but just an atom thick, it’s quite flexible yet with diamond like hardness it is 200 times stronger than steel, it’s incredibly light yet very tough, and it’s a superb conductor but also fire proof. At The University of Manchester, which we will get to in a moment lists the following categories of graphene research applications that they focus on: Biomedical; Sensors; Energy; Membranes; Composites and Coatings; and Electronics. More on the practical applications of graphene in the video below, but another of its major advantages is that it can be produced (in an ink-like solution) relatively cheaply.

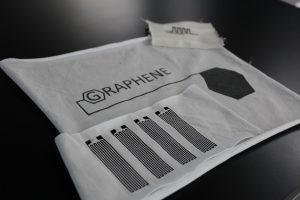

Researchers at the University of Manchester have taken another big step in showing how graphene’s conductivity, strength, and flexibility will prove instrumental to wearable electronic applications. The team has created solid-state flexible battery-like devices known as supercapacitors that can be applied directly on to textiles using a simple screen-printing technique. A supercapacitor is pretty much a battery that can fully charge devices in seconds.

In the paper published in the journal 2D Materials, Dr. Nazmul Karim, Knowledge Exchange Fellow, the National Graphene Institute and co-author of the paper said: “The development of graphene-based flexible textile supercapacitor using a simple and scalable printing technique is a significant step towards realizing multifunctional next generation wearable e-textiles, “It will open up possibilities of making an environmentally friendly and cost-effective smart e-textile that can store energy and monitor human activity and physiological condition at the same time”.

Dr. Amor Abdelkader, another co-author said: “Textiles are some of the most flexible substrates, and for the first time, we printed a stable device that can store energy and be as flexible as cotton. The device is also washable, which makes it practically possible to use it for the future smart clothes. We believe this work will open the door for printing other types of devices on textile using 2D-materials inks.”

Video Transcript:

0:27

I’m a chemist, I work at the molecular level, I’m interested in atoms and molecules and

0:32

the way we can use them and do things which help us all with them. It’s strong, it’s

0:38

light, it’s flexible, it has quite remarkable electrical and thermal conductivity, it’s

0:45

a perfect barrier to the smallest atoms that you can imagine, as well as having an enormous

0:51

amount of surface which is something we can use in all kinds of practical applications.

0:57

The work which won the Nobel Prize winner’s their Nobel Prize was to isolate a single

1:03

layer of graphene by taking graphite and tearing the layers apart, quite simply using sticky

1:09

tape. The idea that you can have a single layer of atoms that act as a perfect barrier

1:15

is something really exciting and really interesting. We believe that graphene in conjunction with

1:21

other things that we’re developing here at Manchester can help us to make much better

1:25

membranes for many processes from, water treatments through to gas separations such as carbon

1:31

dioxide removal through to other liquid separations, such as the purification of industrial and

1:38

pharmaceutical products.

1:42

As academics conducting research we know that graphene has lots of interesting properties

1:47

and enormous potential. We should be able to use this material for

1:52

various applications like anti-corrosion coating, chemical protection coating and also for food

1:59

packaging. One of the potential applications for graphene oxide is water filtration, we

2:04

have to do more fundamental research to make use of this membrane for the desalination

2:09

application so we are working with our industrial partners to use this membrane for water filtration.

2:15

But of course to get graphene into the marketplace we do need help from companies and the people

2:21

who really know what’s needed and who really understand the technical problems of applying

2:28

these materials in real use. We are trying to match what we’re doing

2:32

as academics in the laboratory to what’s needed by companies out in the real world.

2:39

Potentially enormous markets haven’t yet been touched. If we think about carbon dioxide

2:44

removal from power station flue gasses that’s not yet done on any scale and people are still

2:50

arguing about the best way to do it. But if we can generate membranes which will achieve

2:55

that economically then that is an enormous market which will open up which doesn’t

3:01

yet exist. Manchester has a lot of wonderful people already

3:04

working on graphene, but not only that we have an excellent infrastructure. We’ve

3:09

got a lot of facilities close together and we have the ability for people like me in

3:13

chemistry to interact with people in physics, in material science, in chemical engineering

3:19

and in other schools and departments across the university. Manchester’s strength is

3:23

that more than any other place we have people of different disciplines able to work together

3:30

to achieve a common goal.