Credit: Massachusetts Institute of Technology

The main role of a water distribution system is to provide water to consumers with pressurized safe drinking water to all consumers. Public water systems depend on distribution systems to provide an uninterrupted supply of appropriate quality, necessary quantity with adequate pressure. Limited new natural water sources, along with a rapidly increasing world population has led to the need for innovative methods to efficiently manage our water distribution systems. One of the main requirements of a good water distribution system is that it remains water-tight to keep losses due to leakage to a bare minimum.

The challenge is that many of the world’s water distribution systems especially in the developing world, use inferior materials like wood, concrete, clay, or plastic pipes. Overall 20 percent of our world’s water supply is lost because of leaks, which not only adds to the shortages problem but also it leads to a litany of issues:

- Contaminated supply as polluted water gets into the leaking system.

- Serious structural damage, such as eroding foundations of key infrastructures like buildings, underground utilities, and roads.

Current leak detection systems are expensive and don’t work well with older inferior piping so a new approach is needed. Professor of mechanical engineering Kamal Youcef-Toumi and his team at MIT have reportedly been working on a new system for nine years that promises to detect leaks with pinpoint precision, no matter what the piping material is made of. The new system will be demonstrated in detail this September at the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS).

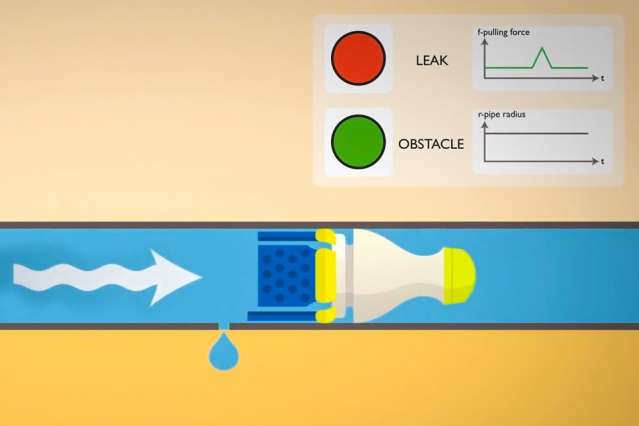

The approach is a clever inside job with no digging or drilling required and no need for any interruption of the water service. Instead, a small, rubbery robotic device is introduced into and retrieved from the water distribution system through convenient openings like fire hydrants. The robotic device, which looks like an oversized badminton birdie, moves passively with the flow or with an active version that can control its motion. As it moves through the piping it works by sensing the pull at the edges of its soft rubber skirt, which fills the diameter of the pipe, to detect even small variations in pressure. It logs its position as it as it navigates through bends, T-joints, and connections until the device is retrieved and its data is then uploaded.

The next step for the MIT team, called PipeGuard, is to commercialize its robotic detection system and make a more flexible, collapsible version of their robot that can quickly adjust itself to pipes of different diameters seen throughout the world and even in the same cities. In the not so far future, the team hope to equip their robotic detection device to also make instant repairs at least with small leaks with a special mechanism they have already designed. The PipeGuard team has successfully tested their leak detection system in Monterrey, Mexico where an estimated 40% of its water supply is lost to leaks every year, at a cost of $80 million annually. And In Saudi Arabia sponsored and collaborated with King Fahd University of Petroleum and Minerals, where 33% of drinking water is lost through leaks in a system that requires very expensive desalination plants. They also have won a slew of awards and prizes for their

- Prize winners at the Booz Allen Hamilton Data Analytics Award.

- Won the 2017 MIT Water Innovation competition.

- One of 25 nationwide Infy Maker Award from Infosys Foundation winners.

- Finalists in the MIT Entrepreneurship Competition.