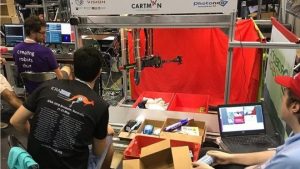

Credit: Australian Center for Robotic Vision

Amazon continues to find better ways to improve the back end of their delivery system to meet customer demand and cut costs too. The giant online retailer is opening new warehouses and distribution centers. And they just announced they’re going to hire 5,000 home-based workers to join its customer service, teams. The pay isn’t great at $10, but the hours are flexible and will come with full benefits, with more details and the application process here. But in the future, it looks like Amazon will not be hiring many new shipping clerks, as that job will go to robots. That is when the robots are sophisticated enough that they can handle the job.

Amazon already has some of the most heavily automated warehouses in the world, but customers’ orders are strictly handled by humans because robots cannot yet reliably handle the task of identifying a wide range of different objects. So every year Amazon hosts a robotics challenge to test out robots that have been programmed to find and pick out merchandise. Amazon set up the difficult four-day challenge this year in Japan, to better simulate warehouse conditions. The teams had only 30 minutes for their robots to learn the particular set of objects they would be tested on, before trying to pick them out of a pile of items.

The winner, a robot called Cartman (South Park influence?) which profited its creators with a $63,770 cash prize, was built by the Australian Centre for Robotic Vision (ACRV). Cartman known as a Cartesian style robot uses grippers with suction tipped fingers moving in 3 axes along straight lines like an arcade claw crane swooping down on stuffed animals (or like this recycling robot), unlike many of the competitors which used more human-like robot arms to carry out the tasks. According to Anton Milan, one of Cartman’s creators said, the bot’s computer-vision systems were a big difference maker to the victory as “We needed seven images of each unseen item for us to be able to detect them.” Another very impressive thing about Cartman is that the ACRV team were able to build the robot with mostly off-the-shelf materials for less than $24,000. That is cheap by industrial robot standards and the lowest cost robot of the 16 teams at the event.